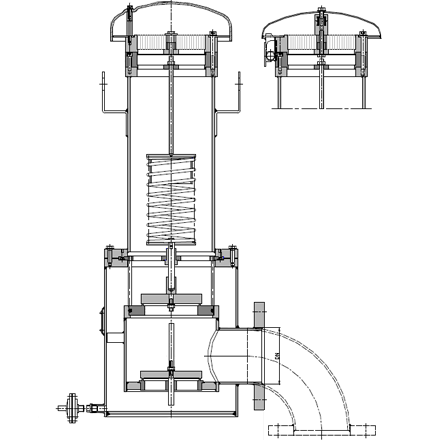

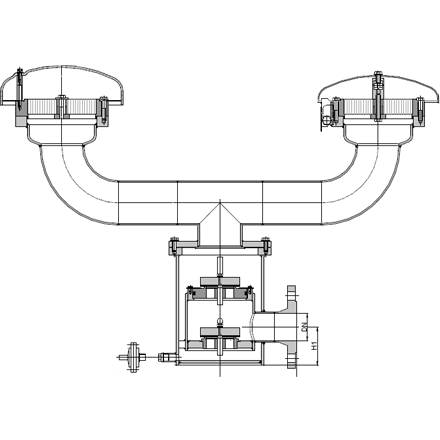

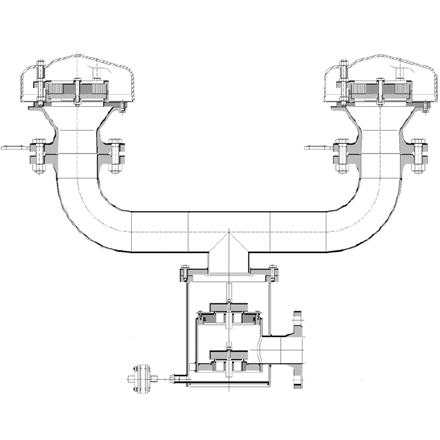

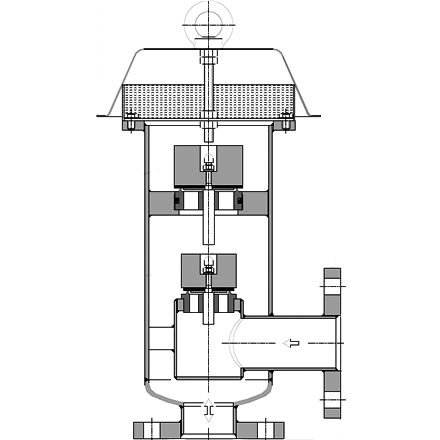

Deflagration and endurance burning proof pressure and vacuum relief valves

KITO® VD/KS-IIA-…-A, K

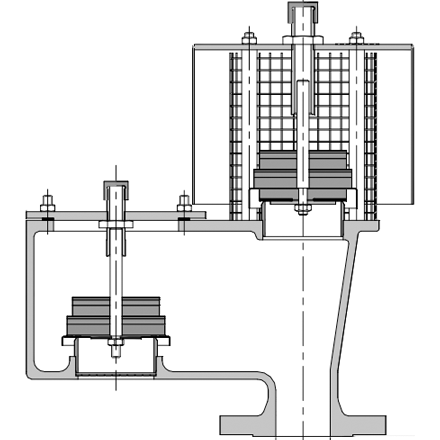

- Certified for explosion group IIA substances with a maximum experimental safe gap (MESG) > 0.9 mm

- Primarily deployed on fixed roof tanks to facilitate venting and inbreathing operations.

- Aims to prevent excessive pressure or vacuum along with minimizing vapor loss and emissions.

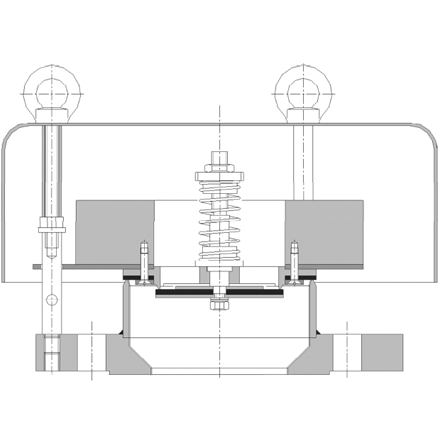

- Mounted atop storage containers for optimal functionality.

- Offers an optional explosion- and endurance burning-proof condensate drain device.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!