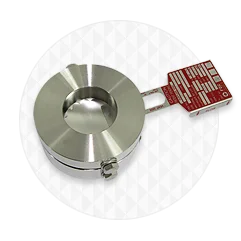

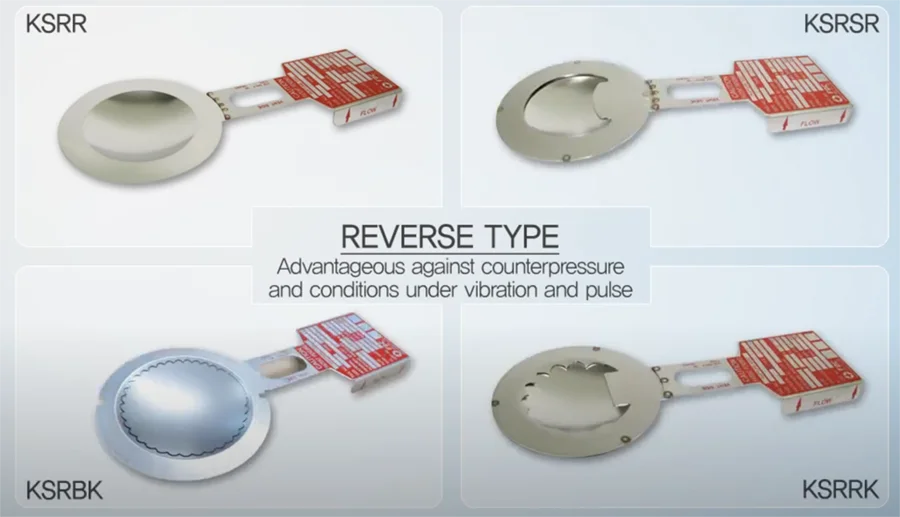

Reverse Buckling Bursting Discs

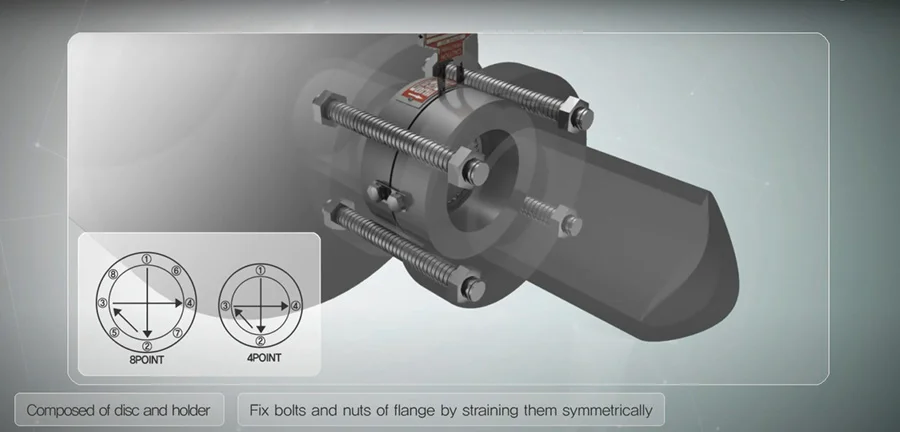

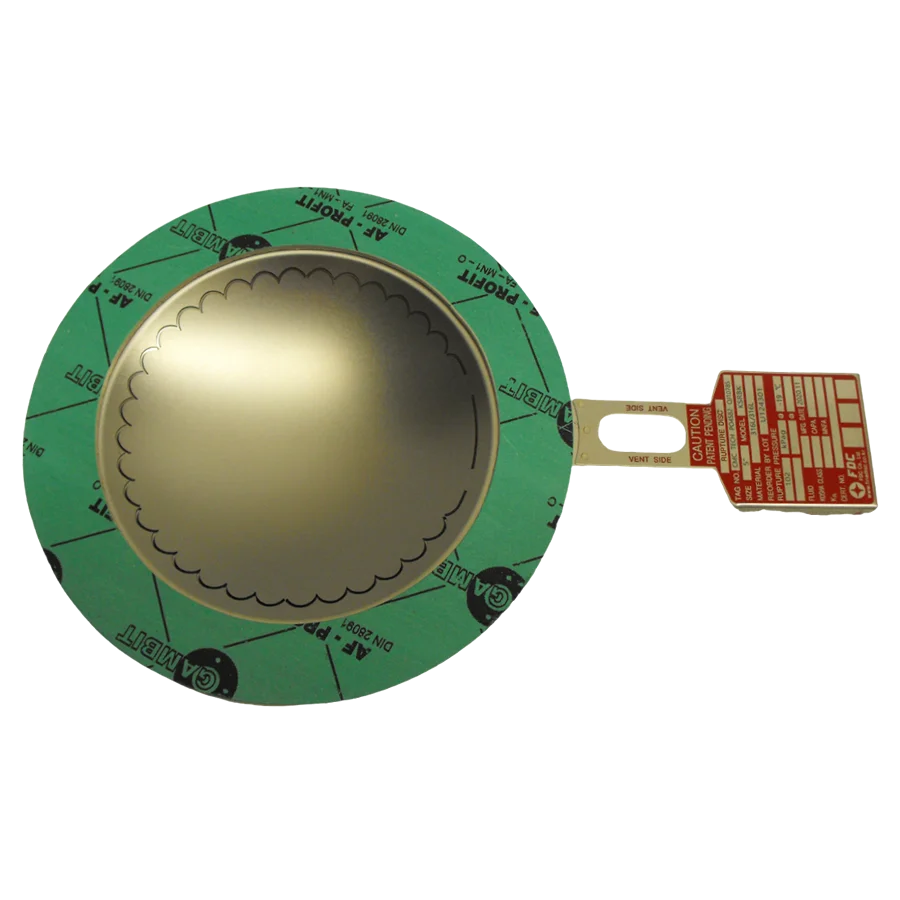

A compression loaded or reverse buckling rupture disc is installed into a system where the normal operating pressure is on the convex side of the formed crown. Reverse buckling discs are available in scored, sheared, or knife types. The dome reverses at the set pressure and then either opens along the scored grooves which part or the dome is cut or sheared in other designs.

It is essential to select the correct reverse buckling disc design for the duty. For example, a cross-scored design would be suitable for gas service and liquids in some cases, while a circular-scored design would be suitable for either gas or liquid or dual-phase service conditions.

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!