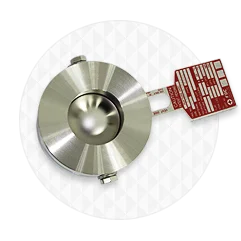

Forward Acting Rupture Disc Tolerance And Installation

This type of disc is installed in a system where the normal operating pressure is on the concave or cupped side of the pre-bulged crown. These discs can be generally operated reliably from vacuum to 70 or 80% of their rated burst pressure depending on the desn. Designs range from Prebulged, Composite or scored designs. Duties are for liquid or gas service depending on the design. Holders can be insert or pretorque type with either flat or angular seted designs. FDC makes some disc designs also suitable to be installed between flanges without the need for holders. Their products can be specified to product standards including KS B ISO 4126, KOSHA, ASME Code Section VIII, API RP520, and the ISO-9001:2008 quality system

INTERESTED OR HAVE QUESTIONS? GET IN TOUCH WITH US NOW!