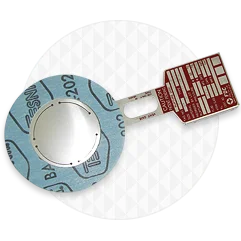

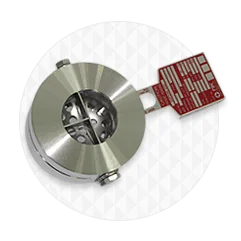

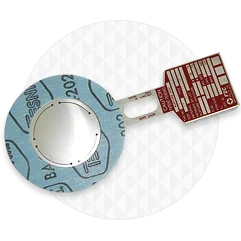

The main FDC pressure relief products are used in various applications that require pressure safety devices such as unpressurised storage containers, different kind of pressurised containers, industrial plants, reactors and ships and related applications.